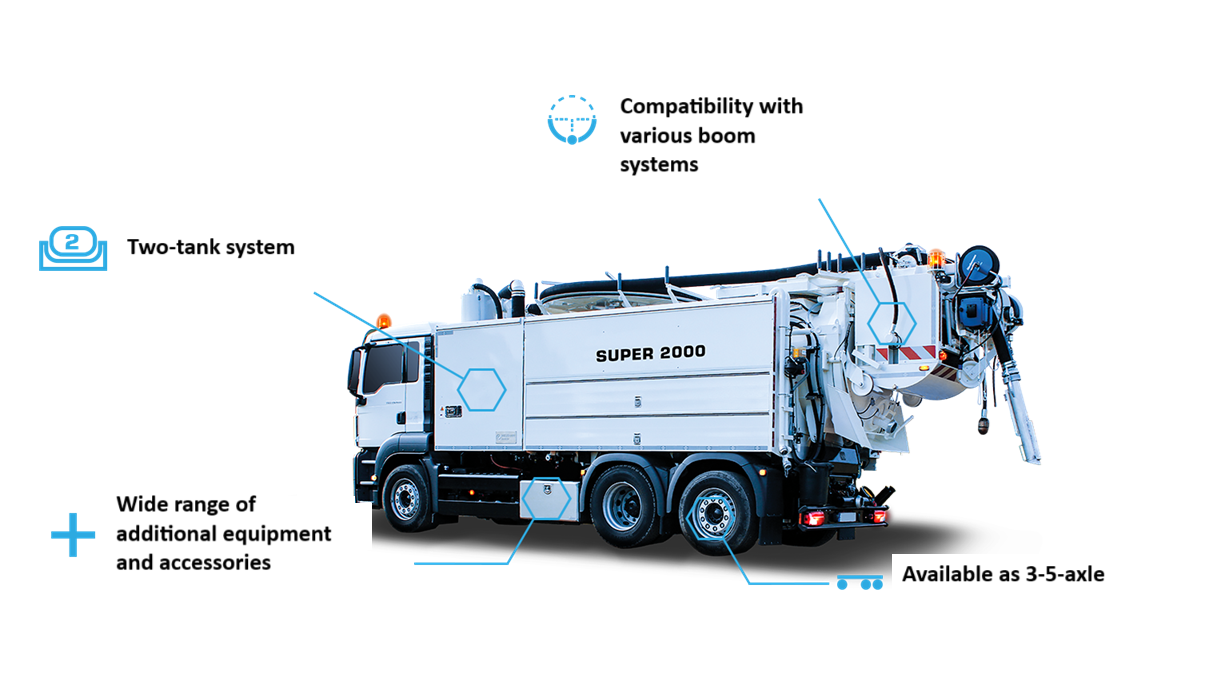

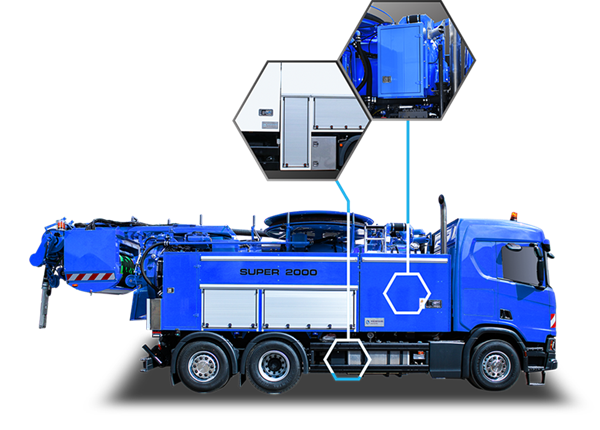

The SUPER 2000 is a sewer cleaning vehicle with two-tank-system, which offers 33% more capacity with the same overall size as a one-tank-system.

The box-shaped water tank is located below the sludge tank and remains in this position even for tilting. As a result, a particularly low centre of gravity and an even weight distribution is achieved in all load conditions, which has a positive effect on the driving characteristics of the vehicle.

In addition, the large sedimentation area in the water tank ensures highly efficient multi-stage sedimentation as an essential part of physical water purification. This is the guarantee for the high quality of the used water.

With or without waterrecycling.

Барабани для високонапірного шланга (HP-hose reels)

- HP reels available up to a hose capacity up to approx. 300 m DN 32 or 500 m DN 25

At the boom:

- the boom carries along the high-pressure reel while swivelling

- all hoses directly at the workplace

- clearly visible working position

- comfortable passage height

- short wheelbase, small turning circle

Between drivers cabin and sludge tank:

- short overhang, generous headroom at the rear of the vehicle

- ideally suited in combination with booms with a large working area (e.g. SPACER front)

Tandem-hose-reel

- two jetting reels which can be operated separately, simultaneously or synchronously

- mounted at the boom

- designed for 180 m DN 25 (1″) or 160 m DN 32 (1 1/4″) each or combinable

- ideally suited for two HP-pumps

On the top of the tank:

- in combination with SPECTRO 360° boom

- suction hose and HP reel arranged on the top of the tank in the centre of gravity of the vehicle

- optimal weight distribution, short wheelbase, small turning circle

- flat, compact design

Additional reel to be attached to the underride guard

- designed for approx. 300 m DN 38 (1 1/2″)

- for extra-long ranges

- with hose guide, pressure roller, drive and hydraulic connector

- Reel rotation direction electrohydraulically controlled by control panel/radio remote control

Transport reels for suction hoses

- operation by hydraulic motor with multi-disc-brake

- only a transportation reel, no suction can be done through this reel

(suction through the reel on request)

On the side of the vehicle:

- designed for approx. 30 m suction hose DN 75 (3”)

At the boom:

- designed for approx. 15-20 m suction hose DN 75 (3”)

On top of the tank

- arranged horizontally under the suction hose reel

- designed for approx. 30 m suction hose DN 75 (3”)

Tool cabinets

With flaps:

- for one-tank system with a flap, optionally with a hose tray above

- for two-tank system with two flaps on top of each other

- made of aluminium

- With covered gas springs to be fixed in an opened position, lockable

With roller shutters:

- with one or two side by side positioned and lockable roller shutter doors on each side

- available for one- and two-tank-system

Clothes lockers

- with lighting

- foldable clothes rail

- ventilation

- drainage

In pump room / behind pump room doors:

- optionally with heating

Integrated in the vehicle contour:

- arranged at the rear of the vehicle in a low position

- with heating

XXL-Locker:

- suitable for one-tank-system

- high version pulled down between the axles

- with roller shutter

- with heating

Further information on additional equipment for work safety, control units and lighting is available on request.