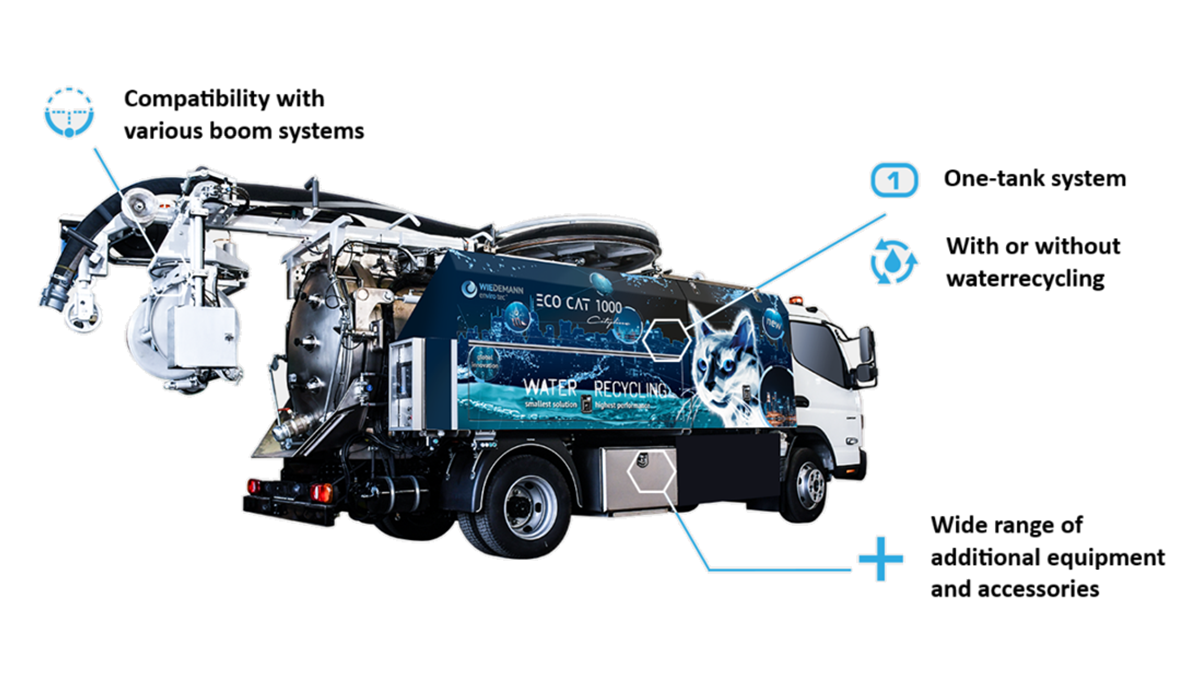

Sewer cleaning vehicle with single-tank system.

The smallest sewer cleaning vehicle with water recycling.

Thanks to its compact design, it is ideally suited for navigating city centers with narrow streets. As an ALL-IN-ONE system, it combines the performance of a small water recycler with the ECO SCOUT camera nozzle: cleaning, accessing, and documenting sewer lines and house connections using the proven WIEDEMANN turning technology.

With or without waterrecycling.

HP-hose reels

- HP reels available up to a hose capacity up to approx. 300 m DN 32 or 500 m DN 25

At the boom:

- the boom carries along the high-pressure reel while swivelling

- all hoses directly at the workplace

- clearly visible working position

- comfortable passage height

- short wheelbase, small turning circle

Between drivers cabin and sludge tank:

- short overhang, generous headroom at the rear of the vehicle

- ideally suited in combination with booms with a large working area (e.g. SPACER front)

Tandem-hose-reel

- two jetting reels which can be operated separately, simultaneously or synchronously

- mounted at the boom

- designed for 180 m DN 25 (1″) or 160 m DN 32 (1 1/4″) each or combinable

- ideally suited for two HP-pumps

On the top of the tank:

- in combination with SPECTRO 360° boom

- suction hose and HP reel arranged on the top of the tank in the centre of gravity of the vehicle

- optimal weight distribution, short wheelbase, small turning circle

- flat, compact design

Additional reel to be attached to the underride guard

- designed for approx. 300 m DN 38 (1 1/2″)

- for extra-long ranges

- with hose guide, pressure roller, drive and hydraulic connector

- Reel rotation direction electrohydraulically controlled by control panel/radio remote control

Transport reels for suction hoses

- operation by hydraulic motor with multi-disc-brake

- only a transportation reel, no suction can be done through this reel

(suction through the reel on request)

On the side of the vehicle:

- designed for approx. 30 m suction hose DN 75 (3”)

At the boom:

- designed for approx. 15-20 m suction hose DN 75 (3”)

On top of the tank

- arranged horizontally under the suction hose reel

- designed for approx. 30 m suction hose DN 75 (3”)

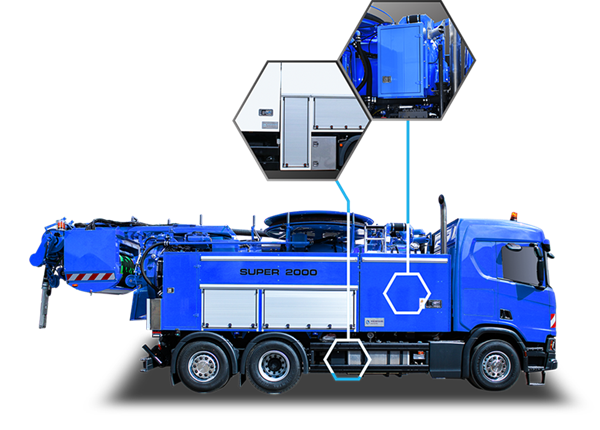

Tool cabinets

With flaps:

- for one-tank system with a flap, optionally with a hose tray above

- for two-tank system with two flaps on top of each other

- made of aluminium

- With covered gas springs to be fixed in an opened position, lockable

With roller shutters:

- with one or two side by side positioned and lockable roller shutter doors on each side

- available for one- and two-tank-system

Clothes lockers

- with lighting

- foldable clothes rail

- ventilation

- drainage

In pump room / behind pump room doors:

- optionally with heating

Integrated in the vehicle contour:

- arranged at the rear of the vehicle in a low position

- with heating

XXL-Locker:

- suitable for one-tank-system

- high version pulled down between the axles

- with roller shutter

- with heating

Further information on additional equipment for work safety, control units and lighting is available on request.